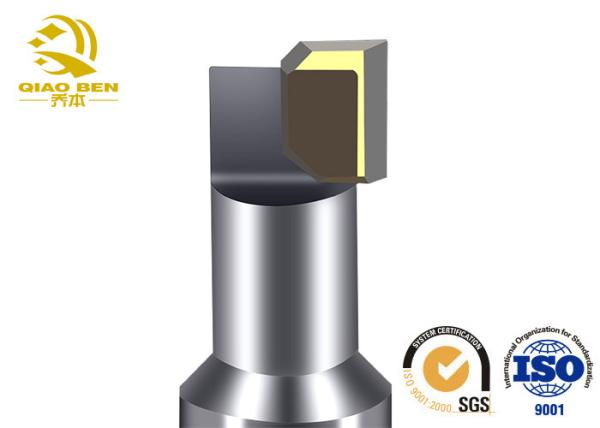

Mono crystal synthetic Acrylic Edge polishing tool diamond tools

Application scope of diamond tools

(1) Processing of difficult-to-process non-ferrous metal materials

When processing non-ferrous metals such as copper, zinc, aluminum

and their alloys, the material is easy to adhere to the tool,

making it difficult to process. Utilizing the characteristics of

low friction coefficient of diamond and low affinity with

non-ferrous metals, diamond tools can effectively prevent metal and

tool from bonding. In addition, due to the large elastic modulus of

diamond, the deformation of the blade during cutting is small, and

the extrusion deformation of the non-ferrous metal to be cut is

small, so that the cutting process can be completed with small

deformation, thereby improving the quality of the machined surface.

(2) Processing of difficult-to-machine non-metallic materials

When machining difficult-to-machine non-metallic materials

containing a large number of high-hardness particles, such as glass

fiber reinforced plastics, silicon-filled materials, and hard

carbon fiber/epoxy composite materials, the hard points of the

material cause serious tool wear, and it is difficult to use

carbide tools. The diamond tool has high hardness and good wear

resistance, so the processing efficiency is high.

(3) Ultra-precision machining

With the advent of modern integrated technology, machining is

developing towards high precision, which puts forward quite high

requirements for tool performance. Due to the small friction

coefficient, low thermal expansion coefficient and high thermal

conductivity of diamond, it can cut extremely thin chips. The

impact on the blade and the workpiece, so the blade is not easy to

passivate, the cutting deformation is small, and a higher quality

surface can be obtained.

| MCD Recommended Cutting Condition |

| Work piece | Cutting Speed | Depth of Cut | Feed Rate |

| (m/min) | (mm) | (mm/rev) |

| Aluminum(5~8% SI ) | 350~1600 | 0.05~2.50 | 0.10~0.40 |

| Aluminum(8~12% SI ) | 350~1300 | 0.05~2.50 | 0.10~0.40 |

| Aluminum(14~18% SI ) | 160~800 | 0.05~2.50 | 0.05~0.25 |

| Copper | 350~1000 | 0.15~2.50 | 0.05~0.20 |

| Sintered Carbid | 15~25 | 0.05~0.60 | 0.10~0.20 |

| Glass Fiber | 100~800 | 0.15~0.50 | 0.03~0.25 |

| Carbon | 160~700 | 0.15~2.50 | 0.15~0.40 |

| High Aluminum | 70~250 | 0.05~1.50 | 0.03~0.15 |

| Ceramics |

| Wood | 1000-2500 | 0.2~5.0 | 010~0.50 |

| Welcome and congratulations!You found us a professional factory! |

| Size & Design | 1.We not only supply all kinds of high quality solid carbide

turning tool ,but also different types of Drill Bits,Reamers,Tool Holders,Cutter

Heads,Saw Blades and Milling cutter,There are diamond grinding wheel, diamond

dressing tools and hardness head. |

2. We have 0.02mm-25mm different diameter and 38mm-150mm length Milling Cutters for your winner market.HRC45/55/60/65 ,1-6 flutes

for you to choose. |

3.OEM:Special Cutters Customized acceptable!Coated OEM also.We can produceaccording to your drawing,too.Or the hot deisgned recommend to you. |

| 4. HS Code reference for you to control everything:8207709000. |

| 5. Mixed size and types in one batch available. |

| 6. For distributor,we can label your brands on cutters and plastic

box. |

| Plating | 1. We accept Mix coated in the same model number, Also one batch

with different coating and types. |

| 2. AlTiN,TiAlN,TiSiN,TiN,DLC,NANO for you to choose to win your

competitors! |

| MOQ (Small Qty ) | 5-10-500-1000-5000-10000 pcs all are welcome. 5 pieces per order is

MOQ. |

OEM One-Step Packing | We package all our goods carefully.We also accept your packing

design OEM packing it for your control. |

| Samples Service | 1. Some items free samples for you. |

| 2. Free samples but pay shipping cost. |

| 3. Lowest shiping fee for you to choose. |

| 4. Order to us,sample fee will be refund to you. |

| 5. Become our VIP clients,free samples for you! |

| 6.OEM samples are hot welcome. |

1. Customers send detailed inquiry to us by email;

2. We reply with price, specifications, packing, photos, and other

details;

3. Both of us agree the price and confirm the details;

4. We write the proforma invoice and send to customers;

5. Customers make deposit;

6. We make mass production samples;

7. We send mass product samples or send photos to customers for

approval;

8. Customers confirm the mass production samples;

9. We start mass production.(we have huge stock for most standard

end mills);

Business Terms

Accepted Delivery Terms: FOB,CNF,CIF

Accepted Payment Currency: USD, CNY

Accepted Payment Type: T/T, Western Union

Nearest Port: Guangzhou port, Shenzhen port, Shanghai port

Response Rate (last 30 days)

98.6% of buyers who contacted this supplier received a response within

24 hours.

Average Response Time (7 days)

The supplier's average response time of received inquiries is

within 12 hours.

Quotation Performance (last 30 days)

The supplier have sent 33 quotes to buyers in last 30 days.

Q: Are you Manufacture?

A: Yes, we are manufacture. we produce our “JOEBEN “brand tools for gurantee the quality.

We also trading related tools for customers because we are in these

field over 10 years, we are very familiar Chinese market tools. we

usually help our customer choose the best suitable related tools

for them.

Q: What is your delivery time?

A: Most of models are ex-stock, if out of stock,there usually need

about 3-5 days or 7-10 days.

Q: Can you produce non-standard tools?

A: Yes, we can produce non-standard tools as per your drawing.

We also can design tools for you as per your usage requirement

Q: What is your advantages?

A: We are factory who produce our own brand “JOEBEN” tools, we must gurantee our brand quality. Also, we have factory

price and fast delivery.

Our advantage:

- 1. 10 years experience in carbide roll and cutting tool

manufacturing

- 2. From row material to tool produdtion.

- 3. World top level prodution equipment and rich experience team

ATTACTION:

- 1. Make sure work piece and machine are stable and use a precision

holder.

- 2. Please adjust the speed,feed and cutting depth according to

actual cutting conditions.

- 3. The milling conditions are for an end mill where the tool

overhang length is less than 4*D(mill diameter). When the tool

overhang length is longer, please adjust the speed,feed and cutting

depth.